Project Description

A multinational pharmaceutical manufacturer was evaluating and rethinking the strategy for its global operation. A new Director was appointed to lead the Tablet Product Stream.

David was brought in to manage change throughout this five-year transformation project.

“To remain competitive, it was vital that we operated in new ways that would transform our performance for the long term. David worked closely with me to change a deep rooted functional organisation to a Lean Supply Chain.” PK, Tablet Product Stream Director

He talked with department managers to understand their perspective and observed the culture at management meetings. It was clear these managers had strong investment in the way things were currently done. The emphasis was on functional power with the biggest departments considered high status; others were viewed as supporting departments. The relationship between these department managers was defensive, often blaming others for problems: and this was also played out lower down the organisation.

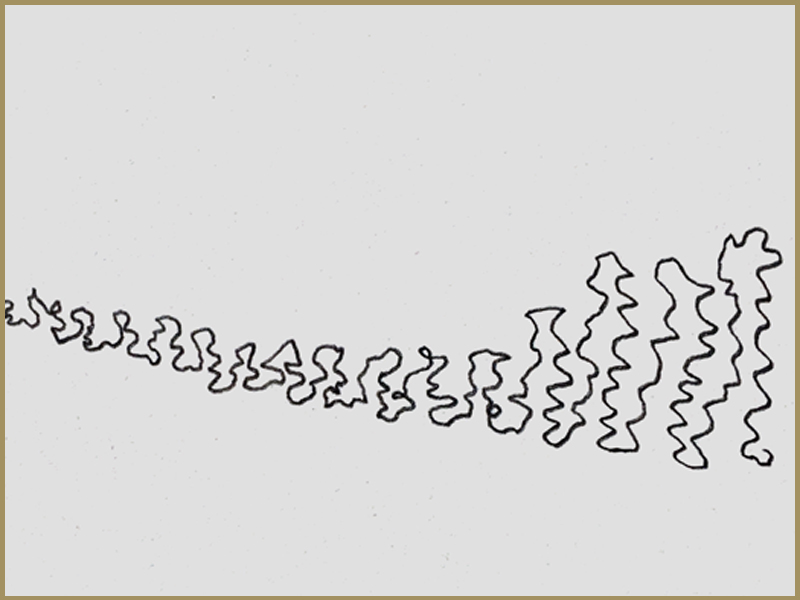

With this cultural understanding, David facilitated a number of ‘breakthrough’ workshops and used different approaches including metaphors, so the managers could see the whole picture, and their place in it. The management team was expanded to include a manager for every department from raw material to customer despatch. No one department was more influential than another. The team met more frequently and one unifying supply chain measure replaced the individual department goals. The culture was shifting from functional to collaborative.

“David’s skills in developing a new management team and the approaches to deliver improvement across the whole supply chain were vital. David brought new ideas and techniques that unlocked people’s thinking and old assumptions.” PK, Tablet Product Stream Director

A supply chain change programme was developed, with each project requiring collaboration between department managers and a clear change management process for the human element of change. Over time the programme gains shifted from defined tasks to how people worked together and at all levels across the supply chain. The shift, with everyone in the organisation acting to reduce overall cycle time meant the business was moving from ‘make to stock’ towards ‘make to order’. Shorter lead times, with reduced operational costs, and developing and sustaining a robust supporting culture – this was the required transformation.

“David also provided the change and implementation support to our most important cycle time reduction projects. The results were essential for future of the business: Over four years the cycle time, from raw material receipt to product delivery, reduced from over 140 days to 28 days. Cost savings exceeded 7 million pounds.” PK, Tablet Product Stream Director